DDDL 8.08 Engineering level available-Unlimited

Description

DDDL 8.08 Engineering level available-Unlimited Detroit Diesel Calibration Tool (DDCT): • View and edit the control parameters in the ECM to... read morePrice

Original price was: $350.00.$300.00Current price is: $300.00.

Total

Original price was: $350.00.$300.00Current price is: $300.00.

Description

DDDL 8.08 Engineering level available-Unlimited

Detroit Diesel Calibration Tool (DDCT):

• View and edit the control parameters in the ECM to optimize the control logic;

• View instrumentation variables, such as rpm or fluid temperatures and pressures;

• Use meta files (.MET), use and edit calibration files (.CAL).

Distributor Reprogramming System (DRS):

• Reprogram an ECM connected to the PC using a new calibration;

• Reprogram an ECM connected to the PC using a Fleet calibration (DDEC III/IV only);

• Update the software in the ECM connected to the PC (DDEC III/IV only);

• View and edit a wide range of customer calibrations;

• View and edit the injector settings (DDEC III/IV only);

• View and edit (DDEC III/IV only) the engine accumulators;

• View the trip accumulators;

• View engine configuration information;

• Extract calibrations from the ECM connected to the PC.

Detroit Diesel Diagnostic Link (DDDL) version 6 – supporting the setting up, maintenance and repair of engines using the DDEC II, DDEC III, DDEC IV and DDEC V Engine Control Modules, and for MBE Engines.

You can use the DDDL to:

• Retrieve and display the current calibration from an ECM.

• Save a calibration for the ECM in an individual truck.

• Save a single calibration with an ECM password, so that the same calibration can be used conveniently for a fleet of trucks with the same password, or can be used by a technician who does not have access to the password.

• Change the engine rating of a truck.

• Set the injector calibration when you replace the injectors.

• Set the ECM clock automatically using the PC’s internal clock.

• View an audit trail of ECM, injector calibration, ECM clock changes and Vehicle Speed setting changes.

• Monitor a wide range of parameters while connected live to the ECM.

• Select a group of these parameters and plot how they have varied over the last two minutes.

• Take and save a snapshot of how the parameters vary over a period of time, so that you can replay the snapshot for detailed analysis.

• Monitor fault codes as they occur while connected live to the ECM. You can also clear any inactive fault codes stored in the ECM.

• Test for faults by checking the effect on performance of cutting out individual cylinders.

• View a record of the injector timings.

• View the ECM output functions and set them to particular values to support troubleshooting. This can be particularly useful when troubleshooting electrical problems.

• Display specific troubleshooting help for any active or inactive fault codes.

• View engine and trip totals.

• View the status of a set of maintenance monitors.

Detroit Diesel Diagnostic Link (DDDL) version 8 – Engineering – can be used on DDEC VI and newer systems:

• View information about the connected ECUs;

• Perform standard fault code operations;

• Perform traditional and advanced troubleshooting;

• Read variable values in real time and display them graphically;

• Configure and manage parameters;

• Perform service routines;

• Play back logs of all connected activity;

• Program the CPC/MCM (EPA07) and CPC02T/MCM2/ACM2 (EPA10).

Related Products

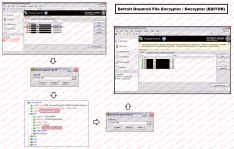

DETROIT DRUMROLL FILE ENCRYPTOR/DECRYPTOR (EDITOR) v0.2

Detroit Original price was: $400.00.$300.00Current price is: $300.00. + Add to cart

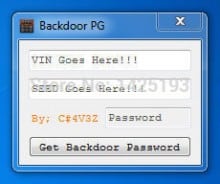

Detroit Diesel Backdoor Passwords 2018

Detroit $250.00 + Add to cart

Address

Address  Email

Email  Phone

Phone